Product Categories

Request A Quote

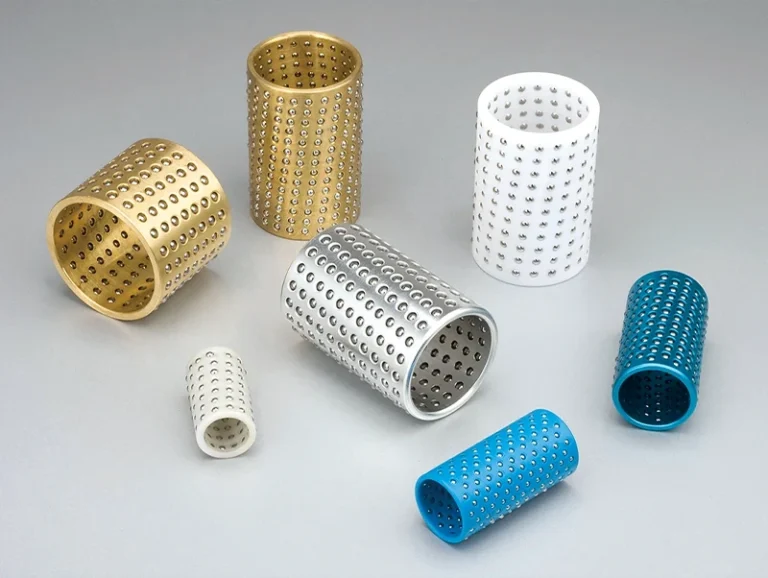

BRT-FZ Ball Retainer Bearing

BRT-FZH, BRT-FZL, BRT-FZP, ball retaining solid are made with respectively, a copper, aluminum, POM base. In its peripheral surface, they are processed orderly, with proper size, shape, and special cavities which have inserted rolling balls. Using the latest trench mouth circumference lock ball technology, it effectively solves the traditional lock balls, but ball indentation-type lock cannot completely prevent the ball off problems.

Product Description

<!–

–>

Intruduction

BRT-FZH, BRT-FZL, BRT-FZP, ball retaining solid are made with respectively, a copper, aluminum, POM base. In its peripheral surface, they are processed orderly, with proper size, shape, and special cavities which have inserted rolling balls. Using the latest trench mouth circumference lock ball technology, it effectively solves the traditional lock balls, but ball indentation-type lock cannot completely prevent the ball off problems. Bottom of the hole machined rabbet 90 ° free rotation of the ball in the hole without falling off. As the ball retainer is greater than the diameter of the wall thickness of the ball up when in use to maintain the circle, the outer peripheral surface, direct contact with the shaft hole match, the base member (retaining ring) floating in the middle, and a hole matching the shaft radius is less than the ball diameter, namely coordinated with the ball for the interference fit, with high accuracy, flexible shaft and hole relative motion. It Is ideal replacements for retaining rings.

Advantages and Application

As the traditional work-craft has some grudge between bushing with posts, and the coefficient of friction is larger. now we have changed the work-ways to steel-ball directly face to face guide bushing, so the precision is improved. it composes of both active roll and lower friction coefficient, now they have been widely used in punching machine, die machine, high precision machine which need rotation and verticaI motion.

Requirements for Installed Components

1. Guide bushing: material GCrl5, YB9, heat treament HRC62-66, technique condition according to GB/T12446. Request 0.01-0.02Mm the surface roughnes

2. Guidie posts: matrial GRrl5, TB9, heat treament HRC62-66, the tolerance of shaft is h5, the surface roughness is

3.Size test: it is tested by outside micrometer & dial gauge as usual. The ymax (ymax+2d’-dmin) request 0.01-0.02Mm