Product Categories

Request A Quote

Product Description

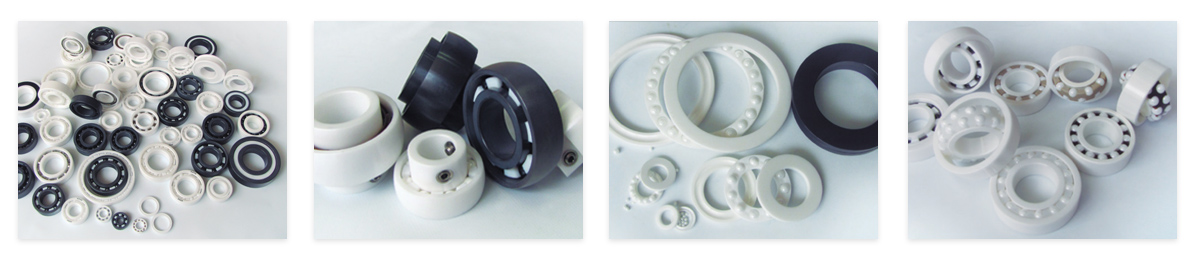

Full ceramic bearing range introduction

With high temperature resistance, cold resistance, wear resistance, corrosion resistance, magnetic electrical insulation resistance, oilless self-lubrication, high speed, etc.properties.Ceramic bearing is a hi-tech product using new materials that can be used in extreme envi-ronments and special condition, and can be widely used in aviation, aerospace, shipbuilding, petroleum, chemical industry, automobile, electronics, metallurgy, electric power, textile, medical equipment, pumps, scientific research and national defense military and other fields.

The ring and roller of our ceramic bearing adopts full ceramic materials including zirconia (ZrO2), silicon nitride (SisN4), silicon carbide (SIC), aluminum oxide (Al203).The cage are made of plastic material:PTFE、PEEK、UPE、PVDF、PA66、SUS304、SUS316, which extends the application of ceramic bearing, high temperature resistant, corrosion resistant, anti magnetic bearings, bearing, electrical insulation bearing, etc.

High temperature resistant bearing:

The material itself has resistance to high temperature 1200 °C, and good self-lubrication, temperature between 100 °C to 800 °C should not produce temperature difference caused by the expansion. Can be used in the kiln, molding, plastic steel and high temperature equipment;

Corrosion resistant bearing:

As the material itself has the property of corrosion resistance,it can be used in strong acid, strong alkali, inorganic salt, organic salt and sea water and other fields such as: Semiconductor equipment,LCD equipment,Food machinery,Electroplating equipment,Chemical equipment,Textile machinery,Medical machinery, shipbuilding and so on.

Magnetically bearings:

As it does not absorb dust,which reduce the early spalling of bearing , large noise, etc. It can be applied in the demagnetization equipment, precision instruments and other fields.

Electric insulation bearing:

As it has high electric resistance,which can avoid arc damage to bearing .It can be applied in power system requiring insulation.

Vacuum bearing:

As ceramic material has unique oilless self-lubrication property,it can be applied in ultra high vacuum environment. It can solve the lubrication problem that can not overcome by ordinary bearings.

Note: We can provide the above five types of bearings.The same set of bearing can be applied to high temperature, acid and alkali, magnetic field, the insulation.As the material performance is different, please inform us your application occasions when you choose our products, we will choose the most suitable ceramic bearing for you.

Full ceramic bearing of ZrO2 material

Full ceramic bearing of Zro2 materials has perfect properties such as high and low temperature resistance, high pressure resistance, corrosion resistance,anti-magnetic insulation and self lubrication, Therefore, it can work in special environment in which hybrid ceramic bearing and earing steel are not applicable.

| RING | BALL | CAGE | Max working Temp. | Anti-corrosion | Application |

| ZrO2 | ZrO2/SI3N4 | PTFE | 180℃ | Excellent | Semiconductor equipment,LCD wel equipment,Food machinery,Electroplating equipment, Chemical equipment,Textile machinery,Medical machinery |

| ZrO2 | ZrO2/SI3N4 | PEEK | 260℃ | Excellent | |

| ZrO2 | ZrO2/SI3N4 | PFA | 180℃ | Excellent | |

| ZrO2 | ZrO2/SI3N4 | PA66/UPE/PP | 90℃ | Good | |

| ZrO2 | ZrO2/SI3N4 | PET | 110℃ | Good | |

| ZrO2 | ZrO2/SI3N4 | FT24 | 180℃ | Excellent | |

| ZrO2 | ZrO2/SI3N4 | PI | 300℃ | Excellent | |

| ZrO2 | ZrO2/SI3N4 | PVDF | 180℃ | Excellent | |

| ZrO2 | ZrO2/SI3N4 | NO CAGE | 300℃~400℃ | Excellent |

Cage material is choose of our company for the details according to different customer service environment requirements and each has it’ s specific use environment please consult the professionals.

Full ceramic bearing of Si3N4 material

Beside all property of ZrO2 full ceramic bearing, Si3N4 full ceramic bearing has the property such as light weight, good wearability and high hardness.The full ceramic bearing with Si3N4 material,compared with the full ceramic bearing with ZrO2 material, is more applicable to high rotational speed and high load capacity and it can resist higher temperature than that of ZrO2. In addition, it has good high temperature strength, mechanical anti-oxida tion capacity, high temperature bearing capacity and can resist corrosive gas.

| RING | BALL | CAGE | Max working Temp. | Anti-corrosion | Application |

| Si3N4 | SI3N4 | PTFE | 180℃ | Excellent | Semiconductor equipment,LCD wel equipment,Food machinery,Electroplating equipment, Chemical equipment,Textile machinery,Medical machinery |

| Si3N4 | SI3N4 | PEEK | 260℃ | Excellent | |

| Si3N4 | SI3N4 | PFA | 180℃ | Excellent | |

| Si3N4 | SI3N4 | PA66/UPE/PP | 90℃ | Good | |

| Si3N4 | SI3N4 | PET | 110℃ | Good | |

| Si3N4 | SI3N4 | FT24 | 180℃ | Excellent | |

| Si3N4 | SI3N4 | PI | 300℃ | Excellent | |

| Si3N4 | SI3N4 | PVDF | 180℃ | Excellent | |

| Si3N4 | SI3N4 | NO CAGE | 1100℃ | Excellent |

Cage material is choose of our company for the details according to different customer service environment requirements and each has it’ s specific use environment please consult the professionals.

Hydrofluoric acid resistant, wear-resistant SIC ceramic bearings

Compare with other types of ceramic materials, full ceramic bearing SiC material is more outstanding in these aspects: higher chemical corrosion resistance, better strength, higher hardness, higher wear resistance, lower frictional properties, and suitable for the highest temperature.

| RING | BALL | CAGE | Max working Temp. | Anti-corrosion | Application |

| SiC | SiC | PTFE | 180℃ | Excellent | Semiconductor equipment,LCD wel equipment,Food machinery,Electroplating equipment, Chemical equipment,Textile machinery,Medical machinery |

| SiC | SiC | PP | 90℃ | Excellent | |

| SiC | SiC | PVDF | 180℃ | Excellent | |

| SiC | SiC | NO CAGE | 1400℃ | Excellent |

Note: This table is recommended for use. In use, it is used as a chemical solution for Japanese gas. It is also used in a mixed acid environment.

99% AlOa ceramic bearings

Al2Oa, full ceramic bearing AlzO3 material which uses 99% Al2O, ceramic material, its rolling parts use AlO, ceramic as well.

| RING | BALL | CAGE | Max working Temp. | Anti-corrosion | Application |

| AI2O3 | AI2O3 | PTFE | 180℃ | Excellent | Semiconductor equipment,LCD wel equipment,Food machinery,Electroplating equipment, Chemical equipment,Textile machinery,Medical machinery |

| AI2O3 | AI2O3 | PEEK | 90℃ | Excellent | |

| AI2O3 | AI2O3 | PA66/UPE/PP | 180℃ | Excellent | |

| AI2O3 | AI2O3 | NO CAGE | 1400℃ | Excellent |

Cage material is choose of our company for the details according to different customer service environment requirements and each has it’ s specific use environment please consult the professionals.

Full ceramic plain bearings

Zro2 matrial \ 90%~99% Al2Oa material \ Si3N4 material \ pressureless sintering SIC material ceramic structure

Main material for full ceramic plain bearing are ZrO2, Si3N4 andSiC ceramic, diversified dimension can be produced according to the customer’ s requirement.

| RING | Max working Temp. | Anti-corrosion | Application |

| ZrO2 | 400℃ | Excellent | Semiconductor equipment,LCD wel equipment,Food machinery,Electroplating equipment, Chemical equipment,Textile machinery,Medical machinery |

| Si3N4 | 1100℃ | Excellent | |

| SiC | 1400℃ | Excellent | |

| 99%AI2O3 | 1500℃ | Excellent |

Cage material is choose of our company for the details according to different customer service environment requirements and each has it’ s specific use environment please consult the professionals.

Full ceramic bearing of full complement balls

Full ceramic bearing of full complement balls has an add-ball gap on its side. Because using no retainer design,the bearing is able to install more ceramic balls than the standard construction, so the heavier load Ability is increased more. In addition, to avoid the limited of the retainer s material,this bearing is the same as the full ceramic bearing of ceramic cage with corrosion and high temperature application. This series of bearing is not proper for high rotation speed.

Stencil ball bearing approval deries

Deep groove ball bearings

Angular contact ball bearings

Thrust ball bearings

UC bearings

Stainless steel 440/S304/S316L bearings, hybrid ceramic ball bearings

Full ceramic bearing with ceramic retainer

To meet the more demanding requirement of high corrosion, higher or lower temperature, ceramic retainer has better performance on wear resistance, corrosion resistance and self lubrication than that with other materials, it s rolling parts use ceramic as well.

Comparision of ceramic material properties

| Properyies | Unit | ZrO2 | SisN4 | SiC | 99AL2O3 |

| Color | White | Gray or black | Gray | Ivory | |

| Prto Density | g/cm3 | 6-6.05 | 3.22-3.25 | 3.15-3.2 | 3.85-3.92 |

| HV Hardness | kg/mm | 1250 | 1600 | 2450 | 1800 |

| Toughness | MN/m | 7 | 6 | 2.5 | 3 |

| Bending Strength | kgf/cm 3 | 100-120 | 80-100 | 40-50 | 30-40 |

| Heat Impact | △T,℃ | 280 | 900 | 400 | 200 |

| aCoef of expansion | x10-6/℃ | 9 | 3.5 | 4.2 | 7 |

| Max Usage Temperature | ℃ | 400 | 1200 | 1500 | 1600 |

| Corrosion Resistance(Acid&Klali) | Good | Good | Excellent | Excellent | |

| Therma I Conductivity | w/mk | 3 | 29 | 120 | 23 |

| Fatigue Life | 80X | 100X | 50X | 40X | |

| Magnetism | Non | Non | Non | Non | |

| Insulation | Insulation | Insulation | Insulation | Insulation | |

| Indentation strength | MPa | 2000 | 3500 | 2250-300 | 2800-3500 |

| Impact strength | Mpa:m-3/2 | 11 | 7 | 45387 | 45326 |

| Weber modulus | GPa | >15 | >15 | >6 | >6 |

| Modulus of elasticity | GPa | 210 | 320 | 410 | 420 |

| Poisson ratio | 0.3 | 0.26 | 0.16 | 0.2 | |

| Resistivity | mm2/m | >1010 | >1014 | 100~2 | >1014~1018 |

| Specific resist ity | mm2/m | 1015 | 1018 | ||

| Specific heat | J/KgK | 400 | 800 | ||

| Degree of circulation (50% vandalism rate) | 50*106 | 50*106 | |||

| Destroy model | Peeling / tearing | Peeling | |||

| Dimension stability | Good | Good | Good | Good |

* Above all, the number of rooms is fixed, the usage situation is different, the membership is changed

Anti-corrosion properties of ZrO2 All-ceramic bearing

| Chemical environment | Molecular formula | Contents% | Temperature | Anti-corrosion property |

| Acetic acid | CH3COOH | 80 | Boiling | Excellent |

| Acetic acid/Acetic anhydride | CH3COOH+CH3CO | 50/80 | Boiling | Excellent |

| Water + sodium chloride | H2O+NaCI | Boiling | Excellent | |

| Carbonic acid | H2CO3 | Boiling | Excellent | |

| Copper | CU | 1400°C | Excellent | |

| Food acid | Boiling | Excellent | ||

| Fruit juice | Boiling | Excellent | ||

| Hydrochloric acid | HCI | 35 | 25°C | Good |

| Chloride + Hydrochloric acid | HCI+FaCI2 | Boiling | Good | |

| Fluorine acid | HF | 25°C | Nomination | |

| Nitric acid | HNO3 | 83 | 25°C | Good |

| Nitric acid + hydrochloric acid | HNO3+HCI | 80+20 | Boiling | Good |

| Phosphoric acid | H3PO4 | 25°C | Excellent | |

| Potassium hydroxide | KOH | 85 | 25°C | Excellent |

| Sodium carbonate + sulfuric acid | Na2Co3+H2SO3 | 80/20 | 925°C | Excellent |

| Sodium hydroxide | NaOH | 50 | Boiling | Excellent |

| Sulfuric acid | H2SO4 | 20 | 25°C | Excellent |

| Sulfuric acid | H2SO4 | 98 | 50°C | Good |

| Aluminum | AI | 100 | 700°C | Excellent |

| Zinc | Zn | 100 | 500°C | Good |